1. Introduction

In the face of mounting environmental challenges, the remanufacturing of waste paper has emerged as a viable and sustainable approach to managing paper waste and mitigating its impact on the planet. Annually, over 400 million tons of paper waste are generated worldwide, with only 50%–65% being recycled, leaving a significant portion to be disposed of in landfills or incinerated (

Nzediegwu and Dumont 2021). Waste newspapers, constituting approximately 7% of the total municipal solid waste (MSW) stream, are a potential low-cost cellulosic material (

Guan et al. 2021). Up to ∼35% of the weight of MSW is waste paper, and the global paper industry is anticipated to produce 500 million tons of paper per year for tissue papers, newspapers, cardboard paper, and shoe sole inserts (

Kolajo and Onovae 2023).

One of the most critical environmental benefits of recycling waste paper lies in reducing greenhouse gas (GHG) emissions. Recycling domestic waste paper has been recognized as a promising approach to achieving this goal. Life-cycle assessments considering the entire process from raw material acquisition to manufacturing, energy production, transportation, wastewater treatment, and chemical production have shown that recycling can lead to a significant reduction in GHG emissions, ranging from 0.8% to 12.2% (

Deng et al. 2023). Furthermore, exporting waste paper for recycling has shown varying impacts on global warming, with potential reductions ranging from 0.27 to 2.25 kg CO

2-eq/kg wastepaper recycled (2019 data) (

Provost-Savard et al. 2023). A case study in Hong Kong highlights the significance of waste paper remanufacturing in reducing greenhouse gas emissions. Waste paper was the second-largest component (24%; 1.7 Mt) of MSW after food waste (30%) in Hong Kong in 2020 (

Chen et al. 2023). With only 32% of the waste paper being recycled and the remaining 68% being landfilled, a considerable amount of CO2-eq was generated from waste paper treatment. By implementing recycling-intensive practices, Hong Kong can achieve significant net GHG emissions reduction (

Chen et al. 2023).

The main use of recycled paper fibers is as a raw material for producing new paper, especially newsprint, thereby reducing the demand for virgin fibers, the amount of waste diverted to landfills, and the overall cost of the paper-making process (

Negaresh et al. 2013). In the pursuit of environmentally friendly waste-paper recycling methods, enzymatic deinking using cellulase or laccase enzymes has gained attention. Traditional deinking processes for wastepaper require various toxic and harsh chemicals that reduce the quality of the paper. Researchers have explored individual and combined use of enzymes, leading to improved deinking efficiency compared to traditional chemical deinking systems (

Akbarpour 2023;

Dixit and Shukla 2023). This approach presents a greener alternative to conventional deinking processes that rely on hazardous chemicals, but the surface chemical composition, fiber crystallinity and morphology, water retention value, and quality of the final paper produced from the processes need to be optimized (

Akbarpour 2023).

The potential of waste paper goes beyond paper production. Studies have demonstrated that waste paper can be converted into activated carbon and adsorbents, making them effective for removing pollutants such as polycyclic aromatic hydrocarbons and phenols from wastewater (

Vishnu Priya et al. 2021;

Nahar et al. 2023). This innovative application not only addresses environmental concerns but also provides a cost-effective solution for wastewater treatment. In particular, waste newspaper has a high susceptibility to absorbing heavy metals (

Wong et al. 2022). The development of cellulose nanocrystals from waste newspapers presents a viable method to improve the physical and mechanical characteristics of polymer composites and value-add the use of waste paper fiber resources to increase economic advantages (

Mohammed Irfan et al. 2023). By subjecting waste newspapers to a simple pretreatment and hydrolysis process, researchers have obtained cellulose nanocrystals that, when added to polymer composites at a ratio of 5%, result in increased tear, tensile, and burst indices (

Guan et al. 2021). This advancement not only enhances the performance of materials but also provides economic advantages through the effective utilization of waste paper fibers. Waste newspaper has been used to prepare environmentally friendly and cost-effective structural materials. Laminates were prepared using layered newspaper and high-density polyethylene film through stearic acid modification and hot-pressing (

Zhou et al. 2023). The composite exhibited excellent mechanical and antimildew properties, making it suitable for panel overlayers in various applications, including building, furniture, and packaging.

The construction industry has embraced the concept of using waste newspapers to create sustainable building materials. Lightweight bricks and concrete, incorporating waste newspapers, offer low-cost and environmentally friendly alternatives to traditional construction materials (

Keerthana Devi et al. 2023;

Sapthagiri et al. 2023). Combining wastepaper sludge ash as an alternative cementitious material to replace cement in ratios up to 5 wt% was demonstrated as an effective strategy to produce low-cost concrete to be used as a novel replacement for traditional concrete (

Keerthana Devi et al. 2023). The management and valorization of waste paper fly ash, an industrial by-product from the combustion of paper recycling sludge and biomass, is an area that demands attention (

Mkahal et al. 2023). Waste paper can be combusted to recover its embodied energy and converted into ash by incineration at 800 °C for 1 h, followed by cooling and sieving (

Wong et al. 2022). The ash is a suitable cementitious material for use in the concrete industry to enhance cleaner production. Carbonation not only delays the setting and improves the stability of the matrix but also contributes to the environmental sustainability of eco-binders. Additionally, co-incineration of sludges with biomass generates waste paper fly ash, which has the potential to be employed as a supplementary cementing material in concrete production (

Wong et al. 2022). The use of wastepaper fly ash as a partial replacement for ordinary Portland cement contributes to reduced GHG emissions and enhanced environmental sustainability of eco-binders (

Mkahal et al. 2023). The replacement of 20% of ordinary Portland cement with carbonated wastepaper fly ash was shown to reduce GHG emissions by more than 27%.

The pursuit of a carbon-neutral future and a reduction in GHG emissions requires innovative approaches to sustainable energy production. Furthermore, the potential for waste newspapers to be transformed into bioethanol, a renewable and eco-friendly fuel, is a promising strategy for addressing sustainable energy demands. Cellulose fibers extracted from waste newspapers can be hydrolyzed into fermentable sugars and subsequently converted into ethanol using Saccaromyces

cerevisae (

Kolajo and Onovae 2023). By converting waste newspapers into bioethanol, not only is the dependence on fossil fuels reduced, but the improper disposal of waste paper is also mitigated. Waste newspapers, rich in lignocellulosic biomass, offer a promising source of fermentable sugars for biofuel production (

Manna et al. 2020). Through enzymatic hydrolysis, fermentable sugars can be recovered from waste newspapers, providing a renewable and environmentally friendly feedstock for biofuel generation. The utilization of lignocellulosic biomass as a carbon-neutral material ensures that the process of fuel generation does not contribute to CO

2 emissions. Furthermore, the use of waste newspaper powder as a source of carbon-based polysaccharides was used as a substrate for the growth of cellulolytic bacteria in microbial fuel cells (

Verma et al. 2023).

Current research priorities in the field of paper waste include the production of valuable products from the waste paper (new paper, levulinic acid, bioelectricity, bioethanol, activated carbon and other adsorbents, biodegradable biocomposites, and structural materials); achieving carbon neutrality; improving the recycling process (strengthening recycled fibers, and deinking and acid hydrolysis of the waste paper); and the use of waste-paper sludge ash for cement-making. Remanufacturing waste paper offers a comprehensive and sustainable solution to address the growing environmental concerns associated with paper waste. Through recycling, resource utilization, green technologies, and innovative applications, waste paper can be transformed into a valuable resource, reducing the burden on landfills and mitigating GHG emissions. The exploration of various techniques and applications for waste paper remanufacturing underscores its potential in shaping a greener and more sustainable future.

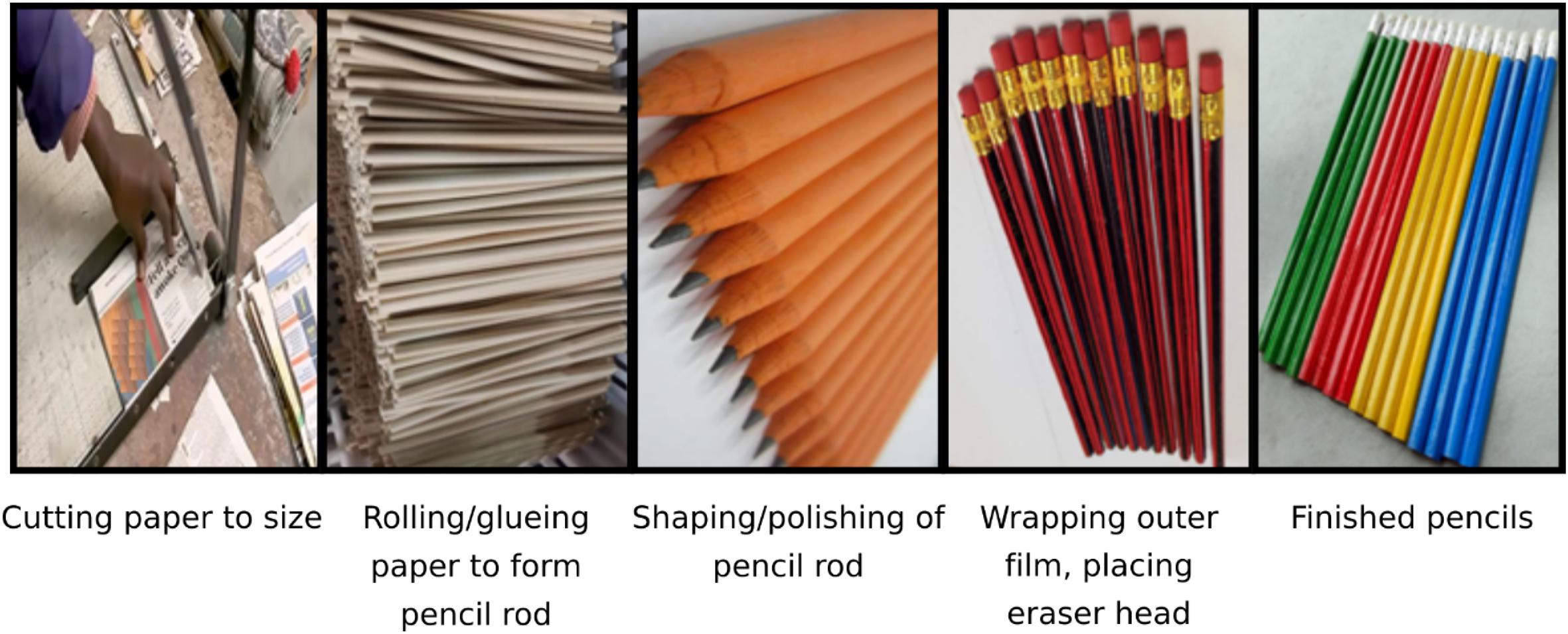

This case study analyzes a specific process involving the recovery of waste paper from MSW, which is then remanufactured into pencils as an environmentally conscious sustainable business to reduce GHG emissions compared to the landfilling/recycling of waste paper and the production of pencils from wood. Henceforth, the term “remanufacturing” is used to mean the recovery of a waste product (paper) and its upcycling into a commercial value-added product. This remanufacturing process is investigated as a specific small-business model that could be widely relevant as it requires only a low investment. While the production of new paper or biomass from waste paper may be more profitable options, they require high investments and are therefore unsuitable for small businesses. It is estimated that over 8 million trees (13 million hectares of forests) are felled annually worldwide, of which 36% is used for paper manufacturing and 42% is used for manufacturing timber-based products, including 14–20 billion pencils (

United Nations 2023). An average tree can produce 170 000 pencils, meaning that almost 100 000 trees are required to produce the billions of pencils used worldwide every year (

Pencil China 2023;

World Atlas 2023). The sourcing of pencil wood is an environmental concern, and in recent decades, many earth-friendly pencils have been commercialized, including those using wood harvested from sustainably managed forests or made from recycled coffee grounds, while some even contain seeds to grow new plants (

ARTnews.com 2022). In addition to deforestation, the forestry industry contributes to environmental impacts related to the trucks and machinery used (

Sharma 2020).

First, a qualitative technical assessment was performed based on regression modelling to evaluate the technical maturity of the required remanufacturing machines with respect to various performance metrics and calculate a technical feasibility index. Then, an economic analysis of five remanufacturing alternatives (with various pencil yields) was performed considering machine investments and labor and energy costs. Then, quantitative technical, economic, and environmental feasibility assessments were performed based on the weighted-sum method and regression plots, while a quantitative–qualitative analysis was performed to analyze the social feasibility of the process on the number of workers and labor costs. In addition, based on the background discussed above, the potential waste paper resources available for pencil remanufacturing were quantified based on literature data for the amount of MSW produced by each country. Finally, the overall sustainability is discussed based on the technical, economic, environmental, and social sustainability metrics and a final sustainability index (SI) was calculated based on weights of importance from the literature. The findings are expected to provide a reference for further sustainability studies of paper remanufacturing, as well as insights for business owners and decision makers in the field of paper recycling.

4. Environmental sustainability

Literature related to MSW, waste paper, and its recycling processes was reviewed to define lower and upper bounds of environmental sustainability remanufacturing potentials based on factors such as the quantity of recovered MSW (obtained from World Bank data), fraction of waste paper in the MSW, saved embodied energy, prevented CO

2 emissions, and data related to the machinery for waste paper-based pencil remanufacturing. The saved embodied energy was calculated based on the comparison with the worst-case scenario of open-air burning of waste paper as biomass, while the CO

2 emissions savings consider the saved energy and the emissions produced during the remanufacturing process. The following constraints and formulas were used to calculate the amount of recovered waste paper, saved embodied energy, and prevented CO

2 emissions as environmental metrics for evaluating the viability of producing pencils from waste paper. The lower and upper bounds of the weight of recovered waste paper (WP

lb and WP

ub, respectively, in Mt) were calculated using

eqs. 1 and

2, respectively.

Here,

F1 = 15% is the fraction of paper in the MSW, which was calculated by multiplying the mean percentage of paper and cardboard in the MSW (25%;

Saeed et al. 2009;

Zhang et al. 2010;

Ionescu et al. 2013;

Joshi et al. 2015;

Czajczyńska et al. 2017;

Malinauskaite et al. 2017;

Abdel-Shafy and Mansour 2018;

Mmereki 2018;

US Department of Energy 2019;

Manna et al. 2020;

Mohan and Joseph 2020;

Rahman et al. 2020;

Stafford 2020;

Hoang et al. 2022;

Center for Sustainable Systems University of Michigan 2023;

International Trade Administration 2024;

Non-ferrous metal prices 2017 – letsrecycle.com 2023;

US Environmental Protection Agency 2023) by 60% as the fraction of paper (

Paper Mart 2022;

Toner Buzz 2023), because cardboard is not suitable for pencil-making. Here,

Flb and

Fub are estimates of the minimum and maximum percentages of useful recovered paper and were set as 13% and 33%, respectively (

Paper Mart 2022;

Toner Buzz 2023). The lower and upper bounds of saved embodied energy (

Elb and

Eub, respectively) were calculated by multiplying WP

lb and WP

ub by 18.44 and 50.44 MJ/kg (

Ashby 2012), respectively, as the embodied energies saved by remanufacturing 100% virgin paper or 100% recycled paper into pencils. The lower and upper bounds of saved CO

2 emissions (CO

2S

lb and CO

2S

ub (Mt CO

2), respectively) were calculated by multiplying WP

lb and WP

ub by 0.785 and 1.18 kg

CO2/kg (

Ashby 2012), respectively, as the emissions prevented by remanufacturing 100% virgin paper or 100% recycled paper into pencils.

Other metrics used in the calculations include 0.441 kWh/kg (or 1.56 MJ/kg (

PPEC 2023)) as the energy required to remanufacture waste paper into pencils according to this study, which corresponds to CO

2 emissions of 0.32 kg

CO2/kg for remanufacturing waste paper into pencils; and 0.2 kg

CO2/MJ was used to calculate the CO

2 emissions directly related to electricity use (

Ashby 2012).

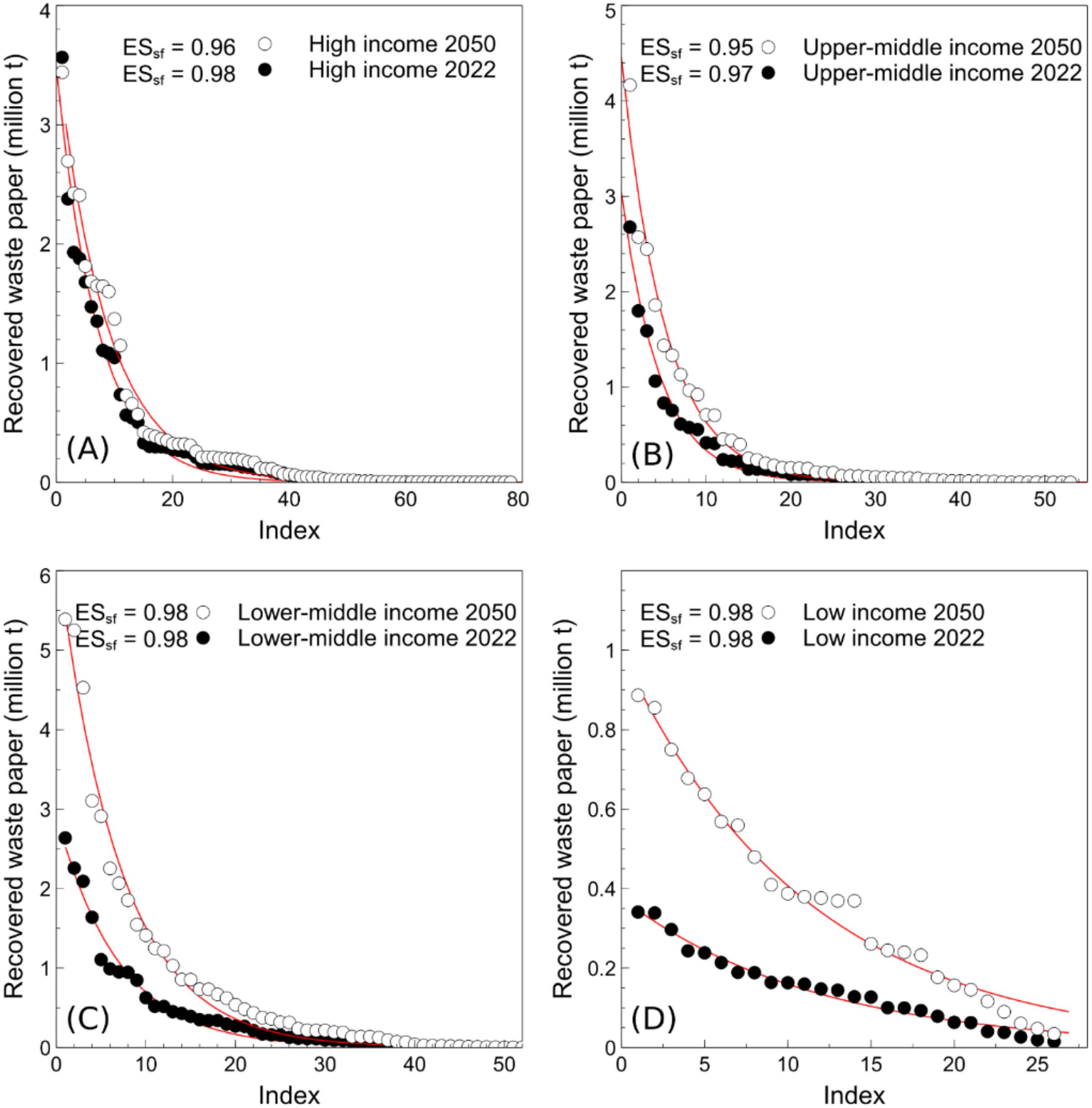

World Bank data related to the production of MSW in all countries was used to calculate the environmental metrics using the equations described above and classified into ten scales: global 2050 scale (

Table 1), global 2016 scale (

Table 2), high-income countries 2050 scale (Table S1), high-income countries 2022 scale (Table S2), upper-middle-income countries 2050 scale (Table S3), upper-middle-income countries 2022 scale (Table S4), lower-middle-income countries 2050 scale (Table S5), lower-middle-income countries 2022 scale (Table S6), low-income countries 2050 scale (Table S7), and low-income countries 2022 scale (Table S8). Both recent data (2016 or 2022) and projections for 2050 are included to enable a comparison of the current and anticipated future sustainability potential of recovering paper waste for pencil remanufacturing.

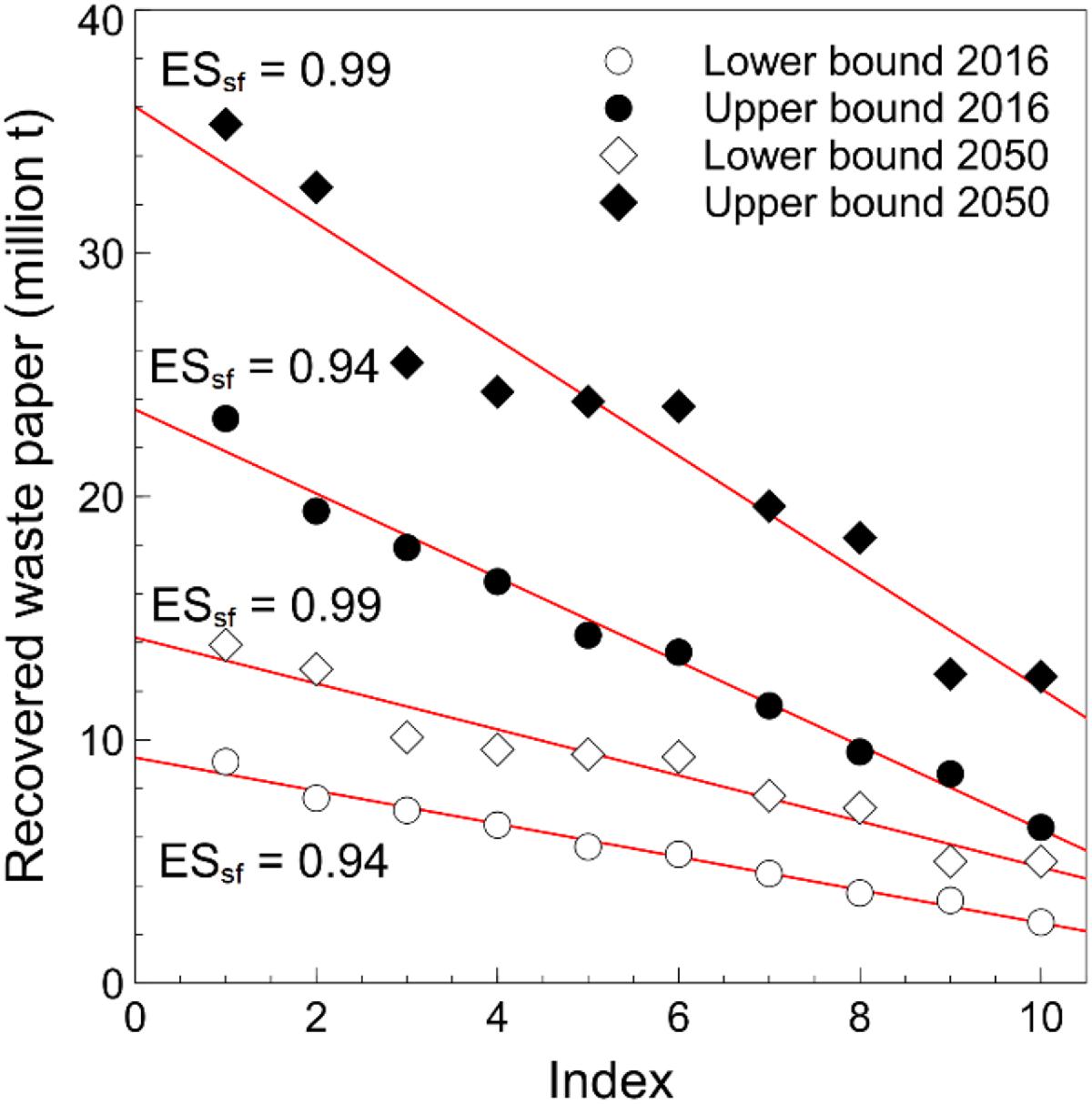

The environmental metrics rankings shown in

Tables 1 and

2 were plotted as regression curves (

Figs. 3 and

4), where the

R2 values of fits to these curves were taken as the environmental sustainability satisfaction factor (ES

sf) values. Only the plots for the recovered paper waste are shown because the other metrics scale linearly with these data and give regression curves with the same

R2 values. The mean of the

R2 values obtained from these figures was taken as the average

E = 0.97. This value exceeds the threshold of 0.7 defined in the literature as the minimum value required to satisfy the multiple-bottom line criteria for developing an environmentally sustainable business (

Du et al. 2012;

Abdullah 2021a,

2021b). Furthermore, divergence from the ideal solution of

E = 1 proves that the solution is reasonable for practical implementation.

This analysis highlighted significant environmental benefits in terms of the annual saved embodied energy (prevented CO2 emissions) of 1168–1783 GJ (27–42 million tCO2) in East Asia and the Pacific, 903–1193 GJ (21–28 million tCO2) in China, 685–1203 GJ (16–28 million tCO2) in India, 479–640 GJ (11–15 million tCO2) in the USA, 16–111 GJ (0.68–2.6 million tCO2) in the Congo, and 6.5–45 GJ (0.28–1.1 million tCO2) in Ethiopia, as representative examples. The lower limit is based on calculations using 2016 data and the upper limit used 2050 predictions.

5. Economic sustainability

Various metrics were calculated to evaluate the economic sustainability of the pencil remanufacturing process. To provide guidance on the viable size of potential small businesses based on this technology, five alternative businesses with different pencil capacities (production per day) are proposed and evaluated. The capital investment costs for the required machines are listed for the five alternatives in

Table 3. Because the investment costs are similar for all alternatives, the higher-productivity alternatives are more economically viable in terms of the payback per day or per pencil. In terms of the energy use of the machines, all lines for all alternatives use 7.44 kW/h or 179 kWh/day, with a total cost of 22 USD/day or 1.64, 1.37, 1.18, 1.03, and 0.92 USD/million pencils for A1, A2, A3, A4, and A5, respectively. These values are based on a global industrial electricity price of 0.121 USD/kWh (2021 data) (

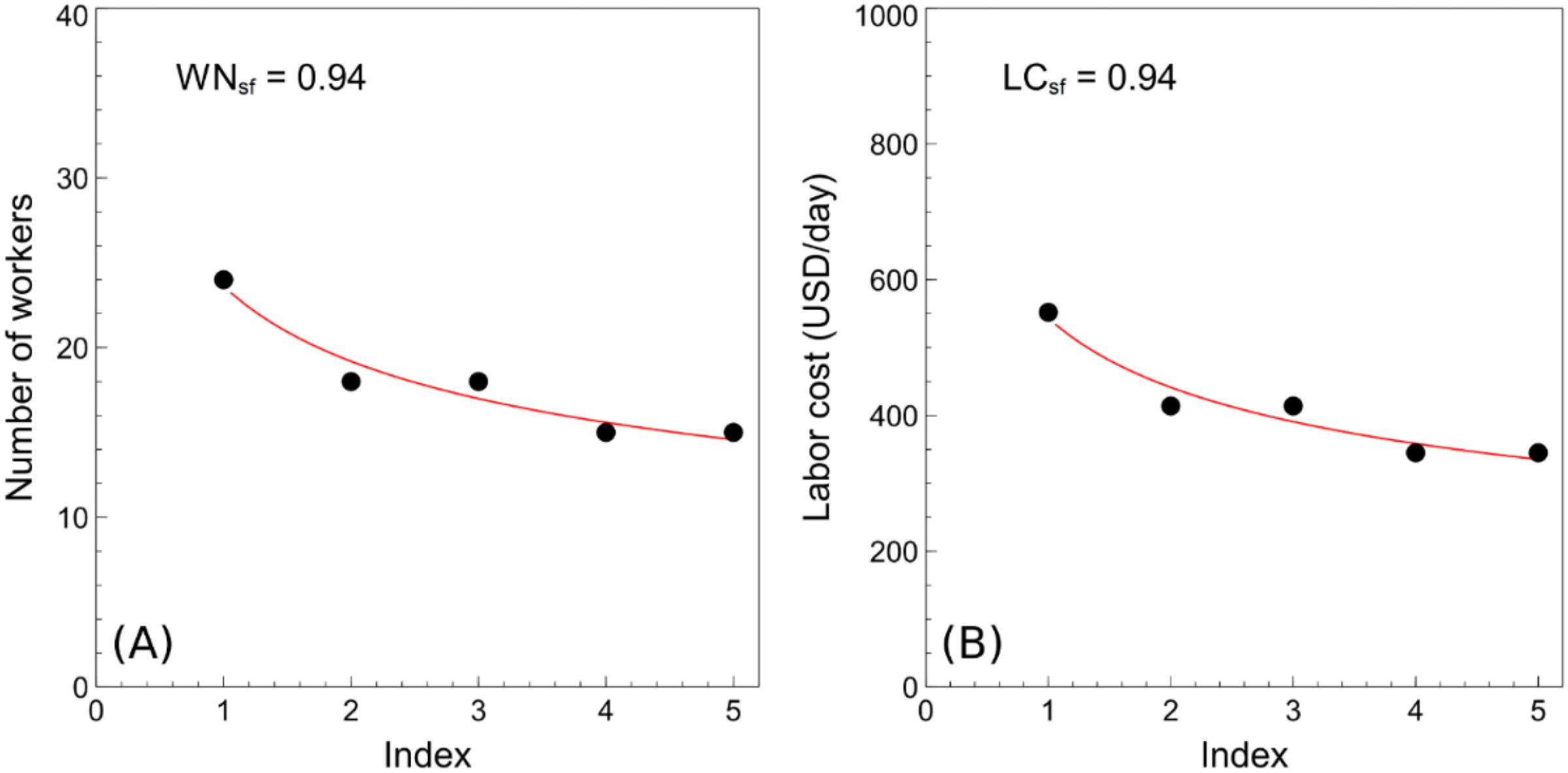

Statista 2023). The delivery and installation costs include the initial delivery of the machines, along with the delivery costs for 6 months worth of raw materials (pencil graphite, erasers, shrink film, and glue). The labor and land use costs for operating the machines and storing paper waste are shown in

Table 4, assuming a single manufacturing line for all alternatives and an average global minimum wage of 23 USD/day. The alternatives with higher capacity (productivity targets) require more/larger machines and, therefore, more workers to operate the machines (and higher labor costs). Based on a machine footprint of 100 m

2 for all alternatives and an industrial land rent cost of 0.25 USD/m

2/day (

Statista 2022), the land use cost is 25 USD/day.

Table 5 summarizes the economic factors of the five alternatives. It was assumed that the pencils can be sold for 0.026 USD/pencil (based on information from the suppliers of pencil remanufacturing machinery and market prices), and waste paper costs 80 USD/ton (

Recycling Monster 2023). It can be seen that A1 has the lowest profit (252 USD/day) and A5 has the highest profit (583 USD/day), where a mean profit of 451 USD/ton is achieved for the alternatives. The lower productivity alternatives earn a lower profit because a higher amount of manual work and labor efforts are required. However, even the lowest productivity alternative A1 (producing 1500 pencil/h) can achieve a reasonable profit for a small, sustainable business.

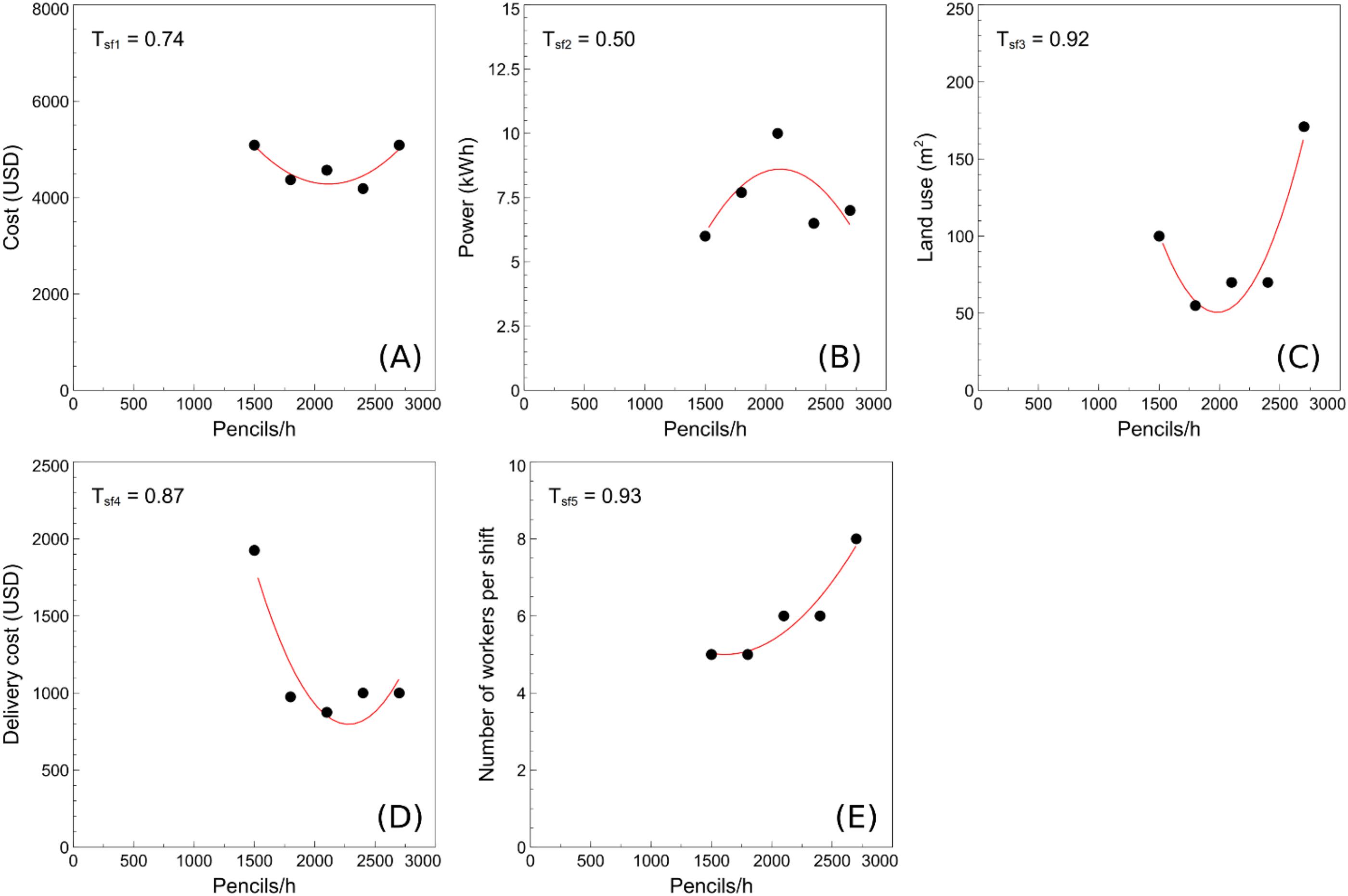

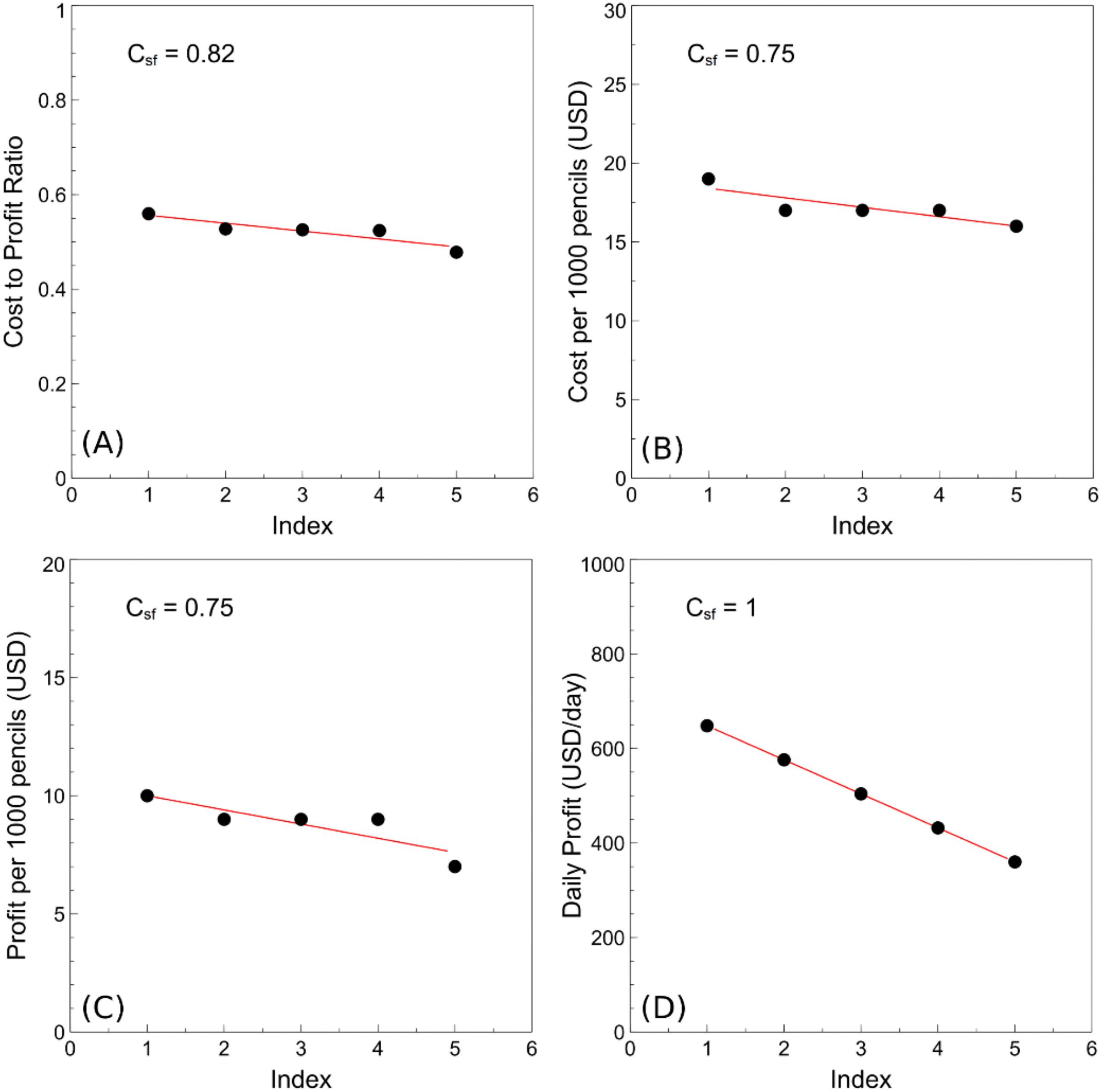

Data related to industrial-scale remanufacturing of paper waste to produce pencils were analyzed to plot regression curves and obtain

R2 values that were defined as the economic SF (

Csf) values (

Fig. 5). The cost-to-profit ratio (alternative ranking of A1 > A3 > A5 > A2 > A4), cost per pencil (A4 > A5 > A3 > A2 > A1), profit per pencil (A4 > A2 = A3 = A5 > A1), and profit per day (A5 > A4 > A3 > A2 > A1) were plotted as regression curves (

Fig. 5) to give

Csf values of 0.82, 0.75, 0.75, and 1, respectively, based on the corresponding

R2 values. These high values indicate a high level of consistency between the economic data. The average of these values was taken as the economic sustainability factor

C = 0.83, which exceeds the threshold of 0.6 required to operate a sustainable remanufacturing business (

Du et al. 2012;

Abdullah 2021a,

2021b), with a reasonable divergence from the ideal solution of

C = 1, indicating a practical sustainable solution.